Construction, Working & Applications of BLDC (Brushless DC Motor)

THEORY, CONSTRUCTION, AND OPERATION 1. Current (dc) motor or generator, the induction motor or generator, and a number. (AC) As it will be shown. Simple animation on working principle of dc generator meant for CBSE class X standard. AC Generator Working Principle and Parts. Laminated structure is used to reduce magnetic losses and also to obtain convenience in the construction.

Table of Contents

- 2 Construction of BLDC Motor

- 5 Advantages of BLDC Motor

Brushless DC motors (BLDC)have been a much focused area for numerous motor manufacturers as these motors are increasingly the preferred choice in many applications, especially in the field of motor control technology. BLDC motors are superior to brushed DC motors in many ways, such as ability to operate at high speeds, high efficiency, and better heat dissipation.

They are an indispensable part of modern drive technology, most commonly employed for actuating drives, machine tools, electric propulsion, robotics, computer peripherals and also for electrical power generation. With the development of sensorless technology besides digital control, these motors become so effective in terms of total system cost, size and reliability.

- Related Post: What is a Stepper Motor? Types, Construction, Operation & Applications

What is a Brushless DC motor (BLDC)?

A brushless DC motor (known as BLDC) is a permanent magnet synchronous electric motor which is driven by direct current (DC) electricity and it accomplishes electronically controlled commutation system (commutation is the process of producing rotational torque in the motor by changing phase currents through it at appropriate times) instead of a mechanically commutation system. BLDC motors are also referred as trapezoidal permanent magnet motors.

Unlike conventional brushed type DC motor, wherein the brushes make the mechanical contact with commutator on the rotor so as to form an electric path between a DC electric source and rotor armature windings, BLDC motor employs electrical commutation with permanent magnet rotor and a stator with a sequence of coils. In this motor, permanent magnet (or field poles) rotates and current carrying conductors are fixed.

The armature coils are switched electronically by transistors or silicon controlled rectifiers at the correct rotor position in such a way that armature field is in space quadrature with the rotor field poles. Hence the force acting on the rotor causes it to rotate. Hall sensors or rotary encoders are most commonly used to sense the position of the rotor and are positioned around the stator. The rotor position feedback from the sensor helps to determine when to switch the armature current.

This electronic commutation arrangement eliminates the commutator arrangement and brushes in a DC motor and hence more reliable and less noisy operation is achieved. Due to the absence of brushes BLDC motors are capable to run at high speeds. The efficiency of BLDC motors is typically 85 to 90 percent, whereas as brushed type DC motors are 75 to 80 percent efficient. There are wide varieties of BLDC motors available ranging from small power range to fractional horsepower, integral horsepower and large power ranges.

- Related Post: Servo Motor – Types, Construction, Working, & Applications

Construction of BLDC Motor

BLDC motors can be constructed in different physical configurations. Depending on the stator windings, these can be configured as single-phase, two-phase, or three-phase motors. However, three-phase BLDC motors with permanent magnet rotor are most commonly used.

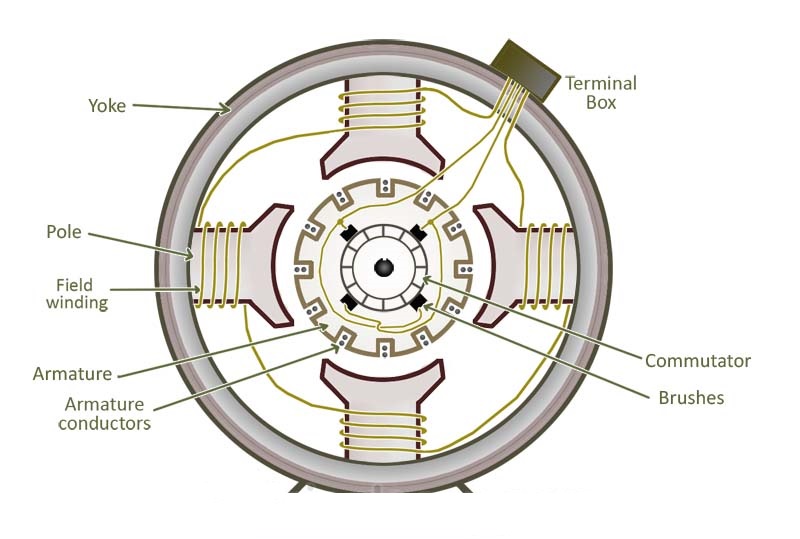

The construction of this motor has many similarities of three phase induction motor as well as conventional DC motor. This motor has stator and rotor parts as like all other motors.

- Related Post Cable Size Calculation for LT & HT Motors

Stator of a BLDC motor made up of stacked steel laminations to carry the windings. These windings are placed in slots which are axially cut along the inner periphery of the stator. These windings can be arranged in either star or delta. However, most BLDC motors have three phase star connected stator.

Each winding is constructed with numerous interconnected coils, where one or more coils are placed in each slot. In order to form an even number of poles, each of these windings is distributed over the stator periphery.

The stator must be chosen with the correct rating of the voltage depending on the power supply capability. For robotics, automotive and small actuating applications, 48 V or less voltage BLDC motors are preferred. For industrial applications and automation systems, 100 V or higher rating motors are used.

- You may also read: What is a Solenoid and Solenoid Magnetic Field

Rotor

BLDC motor incorporates a permanent magnet in the rotor. The number of poles in the rotor can vary from 2 to 8 pole pairs with alternate south and north poles depending on the application requirement. In order to achieve maximum torque in the motor, the flux density of the material should be high. A proper magnetic material for the rotor is needed to produce required magnetic field density.

Ferrite magnets are inexpensive, however they have a low flux density for a given volume. Rare earth alloy magnets are commonly used for new designs. Some of these alloys are Samarium Cobalt (SmCo), Neodymium (Nd), and Ferrite and Boron (NdFeB). The rotor can be constructed with different core configurations such as the circular core with permanent magnet on the periphery, circular core with rectangular magnets, etc.

- Related Post: What is Motor Efficiency & How to improve it?

Hall Sensors

Hall sensor provides the information to synchronize stator armature excitation with rotor position. Since the commutation of BLDC motor is controlled electronically, the stator windings should be energized in sequence in order to rotate the motor. Before energizing a particular stator winding, acknowledgment of rotor position is necessary. So the Hall Effect sensor embedded in stator senses the rotor position.

Most BLDC motors incorporate three Hall sensors which are embedded into the stator. Each sensor generates Low and High signals whenever the rotor poles pass near to it. The exact commutation sequence to the stator winding can be determined based on the combination of these three sensor’s response.

- Related Post Why Electric Motors rated in kW instead of kVA?

Working Principle and Operation of BLDC Motor

BLDC motor works on the principle similar to that of a conventional DC motor, i.e., the Lorentz force law which states that whenever a current carrying conductor placed in a magnetic field it experiences a force. As a consequence of reaction force, the magnet will experience an equal and opposite force. In case BLDC motor, the current carrying conductor is stationary while the permanent magnet moves.

When the stator coils are electrically switched by a supply source, it becomes electromagnet and starts producing the uniform field in the air gap. Though the source of supply is DC, switching makes to generate an AC voltage waveform with trapezoidal shape. Due to the force of interaction between electromagnet stator and permanent magnet rotor, the rotor continues to rotate.

Consider the figure below in which motor stator is excited based on different switching states. With the switching of windings as High and Low signals, corresponding winding energized as North and South poles. The permanent magnet rotor with North and South poles align with stator poles causing motor to rotate.

Observe that motor produces torque because of the development of attraction forces (when North-South or South-North alignment) and repulsion forces (when North-North or South-South alignment). By this way motor moves in a clockwise direction.

Here, one might get a question that how we know which stator coil should be energized and when to do. This is because; the motor continuous rotation depends on the switching sequence around the coils. As discussed above that Hall sensors give shaft position feedback to the electronic controller unit.

Based on this signal from sensor, the controller decides particular coils to energize. Hall-effect sensors generate Low and High level signals whenever rotor poles pass near to it. These signals determine the position of the shaft.

- You may also read: Terms and Definitions related to Motor Control and Protection

Brushless DC Motor Drive

As described above that the electronic controller circuit energizes appropriate motor winding by turning transistor or other solid state switches to rotate the motor continuously. The figure below shows the simple BLDC motor drive circuit which consists of MOSFET bridge (also called as inverter bridge), electronic controller, hall effect sensor and BLDC motor.

Here, Hall-effect sensors are used for position and speed feedback. The electronic controller can be a microcontroller unit or microprocessor or DSP processor or FPGA unit or any other controller. This controller receives these signals, processes them and sends the control signals to the MOSFET driver circuit.

In addition to the switching for a rated speed of the motor, additional electronic circuitry changes the motor speed based on required application. These speed control units are generally implemented with PID controllers to have precise control. It is also possible to produce four-quadrant operation from the motor whilst maintaining good efficiency throughout the speed variations using modern drives.

Related Electrical Drives Articles

Advantages of BLDC Motor

BLDC motor has several advantages over conventional DC motors and some of these are

- It has no mechanical commutator and associated problems

- High efficiency due to the use of permanent magnet rotor

- High speed of operation even in loaded and unloaded conditions due to the absence of brushes that limits the speed

- Smaller motor geometry and lighter in weight than both brushed type DC and induction AC motors

- Long life as no inspection and maintenance is required for commutator system

- Higher dynamic response due to low inertia and carrying windings in the stator

- Less electromagnetic interference

- Quite operation (or low noise) due to absence of brushes

Disadvantages of Brushless Motor

- These motors are costly

- Electronic controller required control this motor is expensive

- Not much availability of many integrated electronic control solutions, especially for tiny BLDC motors

- Requires complex drive circuitry

- Need of additional sensors

You may also read: Three Phase Motor Connection Star/Delta (Y-Δ) Reverse / Forward with Timer Power & Control Diagram

Applications of Brushless DC Motors (BLDC)

Brushless DC Motors (BLDC)are used for a wide variety of application requirements such as varying loads, constant loads and positioning applications in the fields of industrial control, automotive, aviation, automation systems, health care equipments, etc. Some specific applications of BLDC motors are

- Computer hard drives and DVD/CD players

- Electric vehicles, hybrid vehicles, and electric bicycles

- Industrial robots, CNC machine tools, and simple belt driven systems

- Washing machines, compressors and dryers

- Fans, pumps and blowers

You may also read

If commutator is dropped from a d.c generator and induced e.m.f is tapped from an armature directly outside, the nature of such emf will be alternating. Such a machine without a commutator, providing an a.c emf to the external circuit is called an alternator.

Construction of Synchronous generator or alternator:

Generally choice of material is steel to keep down hysteresis losses.The entire core is fabricated in a frame made of steel plates.The core has slots on its periphery for housing the armature conductors.The frame does not carry any flux and serves as the support to the core.Ventilation is maintained with the help of holes cast in the frame.

1) Salient pole rotor:

Let conductor starts rotating from position 1.at this instant, the entire velocity component is parallel to the flux lines. Hence there is no cutting of flux lines by the conductor. So d@/dt at this instant is zero and hence induced emf in the conductor is also zero. As the conductor moves from position 1 to position 2, the part of the velocity component becomes perpendicular to the flux lines and proportional to that, emf gets induced in the conductor. The magnitude of such an induced emf increases as conductor moves from position 1 to 2.